Hot-selling Raised Floor Systems Products - Encapsulated Calcium Sulphate Raised Floor – Senmai

Hot-selling Raised Floor Systems Products - Encapsulated Calcium Sulphate Raised Floor – Senmai Detail:

Advantage

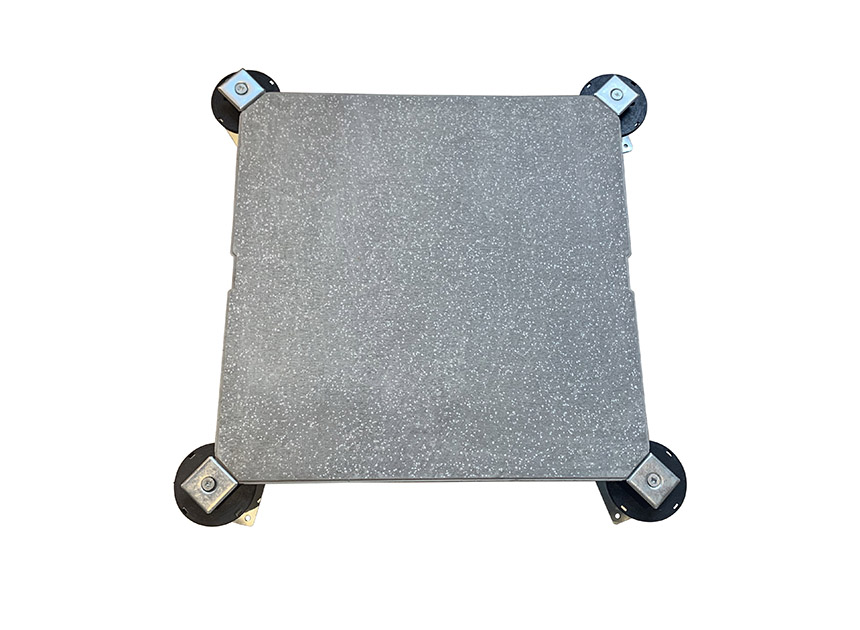

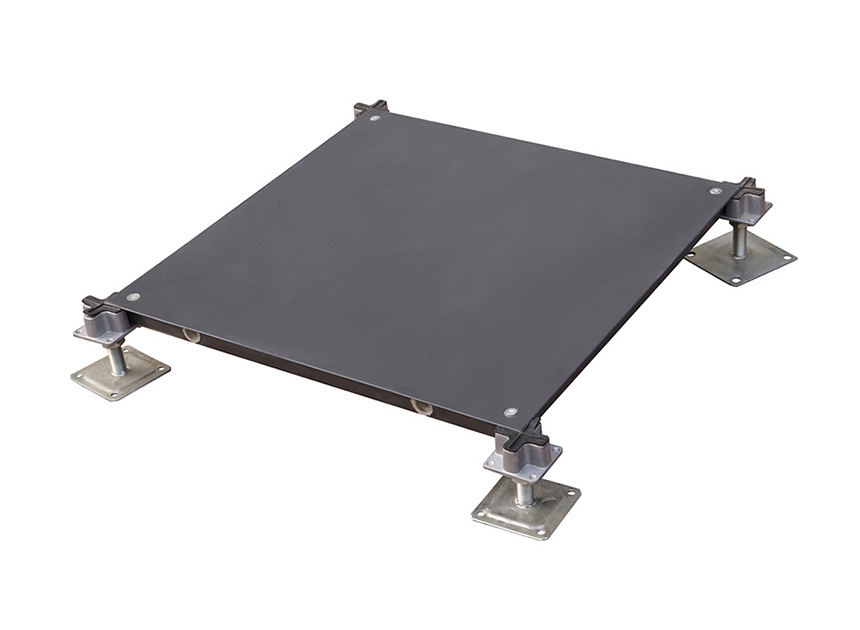

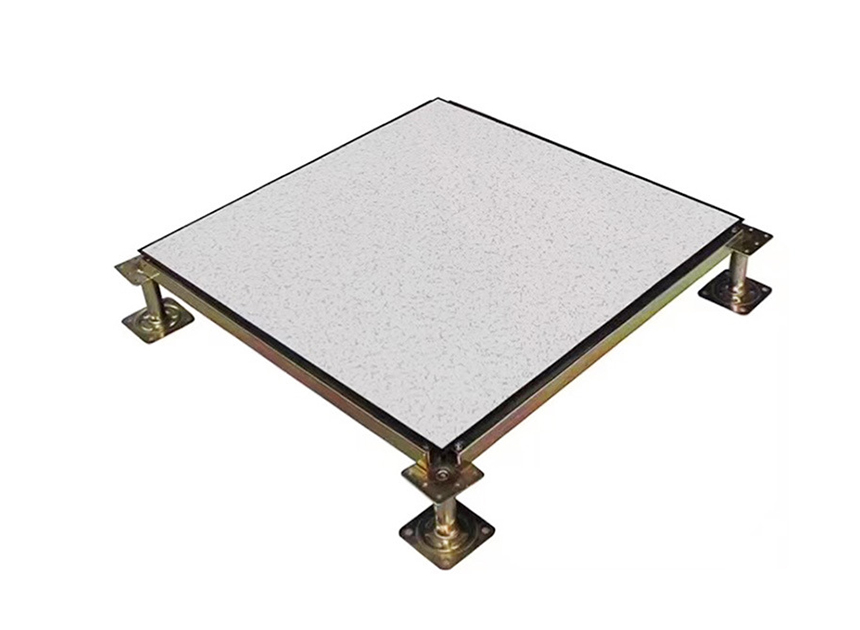

Calcium sulphate network raised floor is made of non-toxic unbleached plant fiber as reinforcement material, combined with solidified calcium sulfate crystal and through pulse pressing process. The pedestal adopts compression molding, and the upper is covered with plastic pad. Its height can be adjusted. The main component of the floor is calcium sulfate (CaSO4•2H2O). When it burns with an open flame, its internal molecules will shed crystal water, absorb heat and evaporate, and form a steam curtain and dehydrated substance insulation layer on the surface, which can effectively reduce the damage to the internal structure by the flame and provide a safer guarantee for indoor personnel and property.

In addition, The floor has good sealing performance, waterproof, high temperature resistance and combustion resistance. The assembly is flexible, the wiring quantity is large, the interchangeability is good, the reuse rate is high, the disassembly is convenient, the cost is saved and the service life is long. The floor has high dimensional accuracy, super load-bearing capacity and pressure resistance, neat and beautiful surface and good flatness. Its structural design is unique, environmentally friendly, pollution-free, and non-radioactive.

Application

It is widely used in 5A office buildings, intelligent office places, senior office and conference hall. It is the most popular high-grade raised floor at present,deeply favored and liked by everyone.

Parameters

| Calcium sulphate encapsulated raised floor | |||||

| Specification(mm) | Concentrated Load | Uniform Load | Deflection(mm) | System Resistance | |

| 600*600*30 | ≥4450N | ≥453KG | ≥23000N/㎡ | ≤2.0mm | |

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Hot-selling Raised Floor Systems Products - Encapsulated Calcium Sulphate Raised Floor – Senmai , The product will supply to all over the world, such as: Iran, Swedish, Bahamas, We are in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.