Massive Selection for Raised Access Floor Tile Lifter - Large bearing capacity GRC access floor – Senmai

Massive Selection for Raised Access Floor Tile Lifter - Large bearing capacity GRC access floor – Senmai Detail:

Advantage

GRC cement raised floor has the characteristics of fire prevention, waterproof, large bearing capacity and long service life. Inorganic silicate has quite good thermal insulation effect and is a non combustible solid. Moreover, inorganic silicate is insoluble in water. In case of water leakage, the quality of the floor will not be affected even if it is completely soaked in water, and it can be used. There will be no rust or corrosion on the cutting edge of GRC floor during paving. Each board of GRC raised floor has its own threading hole. If the amount of outgoing line under the station is not much, there is no need to make a hole on the surface of floor, and it can be directly led out from the built-in outgoing line hole. If the quantity of outgoing lines is large, it can be replaced by one-time molding outgoing line plate without cutting the floor after delivery of the floor, which may result in environmental pollution.

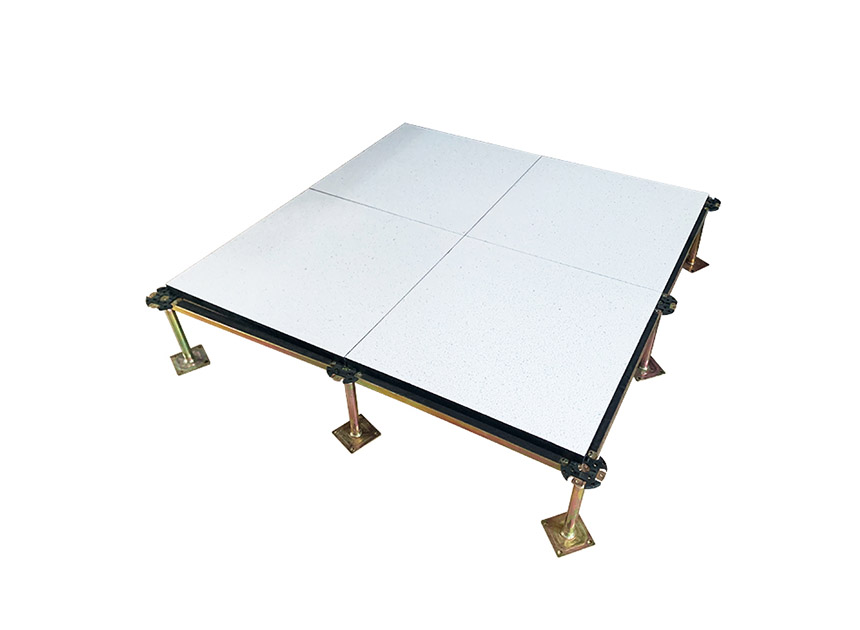

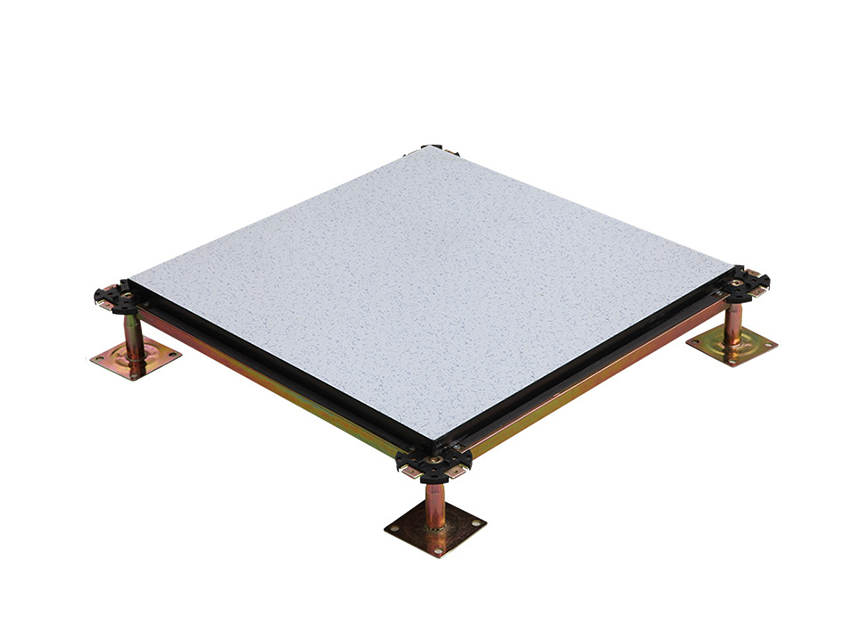

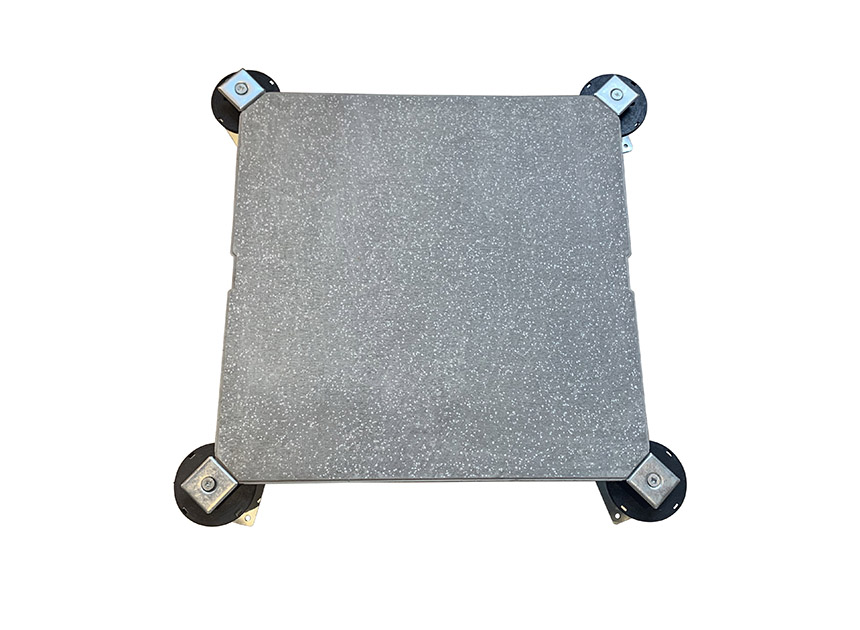

Galvanized base support at four corners of the floor without beam system. The four corners of the traditional GRC network floor are round, and the four plates are combined to form a circle, which is fixed with iron nuts.Our patented technology is four corner oblique cutting, four plates are combined into a square and fixed with square iron nuts. Therefore, compared with traditional technology, the patented technology has better locking performance and more stability. The traditional GRC floor uses yellow sand as raw material, and our company uses quartz sand to enhance the bearing capacity. Compared with other brands of GRC, GRC produced by our company has larger bearing capacity and longer service life. In production, we add an oven to dry the water and improve the product performance. Our packaging is suitable for long-distance transportation and sea transportation.

Parameters

| GRC raised floor | |||||

| Specification(mm) | Concentrated Load | Uniform Load | Deflection(mm) | System Resistance | |

| 500*500*26 | ≥2950N | ≥300KG | ≥12500N/㎡ | ≤2.0mm | |

Product detail pictures:

Related Product Guide:

We goal to see good quality disfigurement within the manufacturing and provide the most effective support to domestic and overseas shoppers wholeheartedly for Massive Selection for Raised Access Floor Tile Lifter - Large bearing capacity GRC access floor – Senmai , The product will supply to all over the world, such as: Singapore, Brisbane, Morocco, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and make sure you feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specs or inquiries today.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.